Video: Gerlach scores in safety tests

Tactical vehicle copes with an 8-kilogram TNT explosion under its cabin to prove incredibly high mine resistance capability

The tactical armoured vehicle Gerlach 4×4, produced by Zetor Engineering Slovakia, has already undergone an entire series of challenging and often extreme tests of its capability. Among other things, its off-road capabilities were tested under the toughest proving ground conditions, on a race track, in snow, sand and even on a motorway. Both noise and the performance of this tactical vehicle’s braking system were measured, while its ballistic resistance was proven in live fire exercises. But it was far from everything the armoured vehicle went through. That was because Zetor Engineering decided to test also vehicle safety by setting off an extra-heavy charge directly beneath the cabin, going beyond standard requirements. Taking into account all costs and work that went into its development, there was indeed the highest confidence in the vehicle’s capability by the manufacturer.

Safety testing

Resistance by light armoured tactical vehicles (LATV), the class the Gerlach 4×4 belongs, to grenade and mine blast is governed by NATO AEP-55 STANAG 4569, with the standard considered to have been met when the vehicle withstands a six-kilogram TNT anti-tank mine explosion under the wheel and below the cabin (Volume2, Level 2a, 2b). However, the bar was raised when it was declared that the Gerlach could withstand a charge two kilograms stronger (Volume 2, Level 3a, 3b). The first test carried out (factory acceptance testing) involved an eight-kilogram TNT charge explosion under its cabin. During testing the cabin was occupied by life-size military figurines. Sensors along with outside and inside cameras were used to obtain exact information about the load on the human body and its responses. The video shows the armoured vehicle withstanding this extreme test and continuing to further testing undamaged.The Gerlach’s cabin is a pressurised armoured capsule fitted independently of the undercarriage to keep the crew safe even beyond ordinary safety standards. They remain protected even if the undercarriage is damaged. The cabin is designed for a SAFETY volume of 7.7 cubic metres. Compared to standard space for four or five people, it has enough room for a six-member crew up to 190 centimetres tall and weighing 120 kilograms including gear. In emergency situations, space can be provided for an additional two crew members (without seats). The cabin is also designed to enable the crew to evacuate it very quickly.

Gerlach’s ballistic protection is also certified under NATO standards at Volume 1 and Level 3, so the crew should have no concerns about firing the hand-held weapons used in current conflicts. This has been independently verified in tests carried out by a reputable company, IBD Deisenroth Engineering GmbH, under the supervision of certification authority Beschussamt Ulm.

Sturdily built and up to 1,300 Nm torque

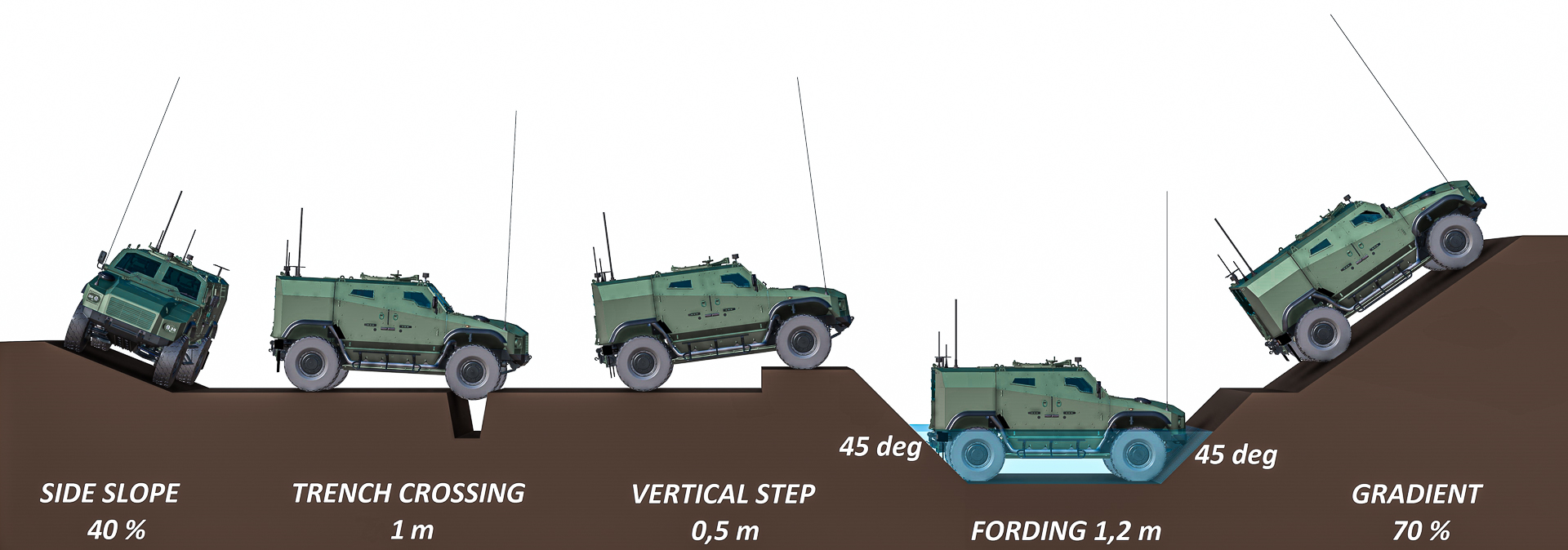

Despite its lightweight construction and kerb weight of 12 tonnes, the Gerlach is sturdily built to overcome extreme obstacles. Besides the knowledge obtained from actual military conflicts and the Dakar Rally, torque up to 1,300 Newton metres and wheel size (R20) are significant factors contributing to its performance.

In tests conducted at military zones, the armoured tactical vehicle surmounted terrain rising 0.5 metres and overcame one-meter wide trenches. While negotiating both obstacles, it was carrying a six-man crew in full battle gear with a total weight of 720 kilograms and a one-tonne cargo in the hold.

The vehicle successfully cleared a “100% slope” with a full 14-tonne load and managed an approach angle of 45 degrees. On long stretches, it comfortably climbed a 60% grade.

Dynamic testing

In tests conducted at the Slovakia Ring racetrack, it surmounted its initially declared parameters, reaching a maximum speed of 125 kilometres per hour in rainy weather. The vehicle also demonstrated its tractive force by pulling a 28-ton tractor and circling for one hour along a circuit while retaining desired temperatures.

The power train’s design, among other things, produced these results. It runs on a German 240-kW, six-cylinder MTU engine, with an output of 240 kW and an above-standard torque of 1,300 Nm. The engine is supported by a 6-gear automatic transmission for maximum power across a wide scale. The independently suspended wheels are powered by a set of uniquely balanced drive shafts through a downward GHM transmission that is among the world’s leaders in torque distribution on all-wheel drives. This design lets the Gerlach achieve exceptional dynamics with a power-to-weight ratio reaching 17.1 kW per tonne.

Crew comfort

When constructing new generation vehicles, crew comfort is equally important, which among other things depends on the level of noise and vibrations transmitted into the cabin. Therefore, the job of the developers is to make sure any disturbances are as minor as possible. In order to verify the results of all action taken here, Zetor Engineering worked with Siemens to conduct special acoustic testing.

A low noise level of 65 decibels was measured in the cabin (where 60 dB equals the noise generated when words are ordinarily spoken).

Parked at a 83.9% slope

The effectiveness of the parking brake system, which can play an important role in crisis situations, was also tested. Armies generally require a military vehicle to remain on a slope, with the engine shut off, inclined 60%, i.e. at an angle of 30°. The tests were carried out on a special tilting platform, whose incline was gradually increased to gauge the limits of the vehicle. The Gerlach was able to remain inclined at a 78% slope (38.2° angle) parked uphill and downhill at an 83.9% slope (40° angle). During testing, the vehicle was carrying the maximum weight of 14.2 tonnes.

Heading to Brno

The new generation Gerlach 4×4 armoured vehicle premiered last May at the IDEB trade fair in Bratislava. It was subsequently exhibited at Sobra 2018 in Slovenia and at MSPO 2018 in Kielce, Poland. At the end of May this year, both professionals and the general public will be able to see and become acquainted with it at IDET 2019, an international defence technology exhibition to be held in Brno. Czech republic.